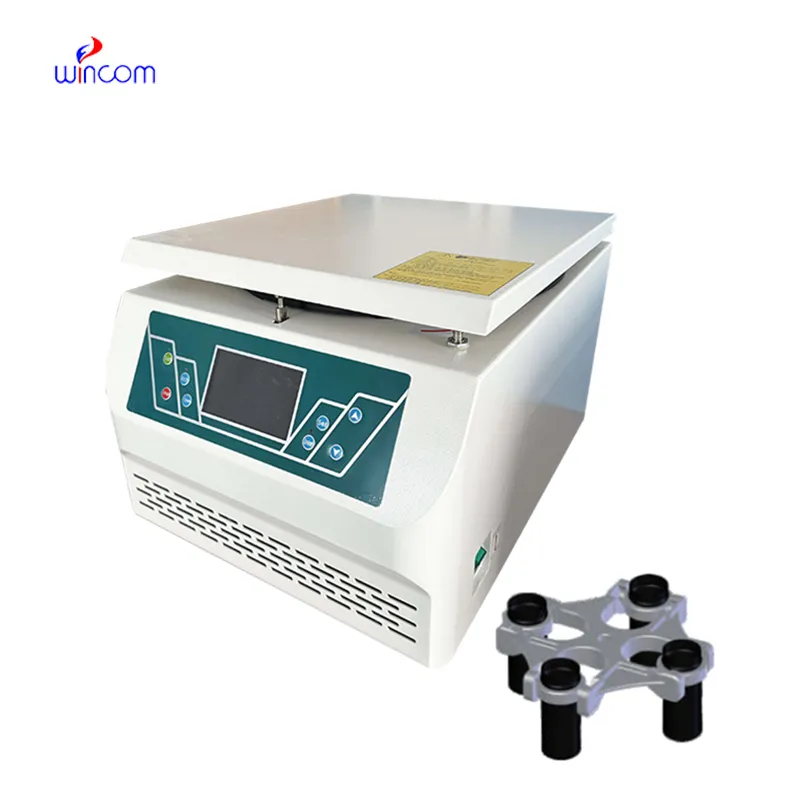

Emerging technologies have driven the performance boundaries of the centrifugal force centripetal force, offering improved acceleration rates and greater throughput of samples. Programmable features and touchscreens give users more control over every operation stage. Temperature-controlled centrifugal force centripetal force in delicate biological processes guarantee specimen stability over extended cycles. Maintenance-friendly designs and auto-diagnostic programs minimize downtime. The adaptability of next-generation centrifugal force centripetal force devices ensures compatibility with any sample type, ranging from microfluidic volumes to industrial suspensions, making it a vital tool in scientific and engineering studies.

The applications of centrifugal force centripetal force span numerous scientific and industrial uses. In medicine, it is used to isolate blood components for transfusion and diagnostic purposes. In molecular biology, researchers use centrifugal force centripetal force to isolate DNA, RNA, and proteins for genetic studies. The pharmaceutical industry uses it to purify chemicals and enhance the quality of products. Environmental laboratories use centrifugal force centripetal force to test water and soil samples for contamination. Even in food processing, it aids in the cleansing of juices and the removal of oils. Its applicability ensures consistent outcomes in fields that require careful separation of substances.

centrifugal force centripetal force will integrate digital intelligence and cutting-edge engineering in the years to come. Complex algorithms will auto-tune parameters for optimum efficiency and safety. Energy-optimized designs will keep operating costs at a minimum and help support global green efforts. Robotics integration will facilitate round-the-clock unattended operation in big production setups. Modular design will provide ease of customization, allowing users to set up centrifugal force centripetal force for specific scientific or industrial uses. These improvements will allow centrifugal force centripetal force to not only increase performance but also establish new standards for automation, accuracy, and sustainability in the lab environments of the future.

Maintenance of centrifugal force centripetal force is essential to lab safety and data integrity. Cleaning should be performed immediately following every operation, with special attention to the elimination of any liquid spills or residues from samples. The rotor should always be handled gently, placed in an upright position during storage, and never subjected to shock. Periodic inspection of lid locks and gaskets ensures airtight operation. Power cord and fuse conditions should also be checked by operators. Annual servicing by skilled technicians adds lifespan. Through regular care processes, centrifugal force centripetal force safely and accurately continues to operate.

The centrifugal force centripetal force is a staple equipment in laboratories, industries, and research facilities. Its operation is to isolate particles away from one another based on density and weight by utilizing centrifugal force. Whether examining biological fluids, purifying chemicals, or testing materials, the centrifugal force centripetal force provides effective separation and purification. Advances in technology have made it faster accurate and automatic, enabling processes to be more repeatable and consistent. From clinical diagnostics to environmental analysis, centrifugal force centripetal force are essential in furthering precision, productivity, and scientific innovation globally.

Q: What safety measures are important when operating a centrifuge? A: Always ensure the rotor is balanced, the lid is securely closed, and safety locks are engaged before starting operation. Q: What types of centrifuges are available? A: Common types include micro, benchtop, refrigerated, and ultracentrifuges, each suited for specific laboratory or industrial applications. Q: Why is balancing samples important for a centrifuge? A: Imbalanced samples can cause vibration, noise, and mechanical stress, potentially damaging both the rotor and the instrument. Q: What materials can be processed in a centrifuge? A: A centrifuge can handle liquids, suspensions, and even some emulsions, depending on its speed and rotor type. Q: How long can a centrifuge run continuously? A: Run time depends on the model and workload—most can operate from a few minutes up to several hours under proper temperature control.

The hospital bed is well-designed and very practical. Patients find it comfortable, and nurses appreciate how simple it is to operate.

This x-ray machine is reliable and easy to operate. Our technicians appreciate how quickly it processes scans, saving valuable time during busy patient hours.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide more information about your microscope range? I’d like to know the magnif...

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China