Small samples for accurate mass measurement depend on the laboratory's electronic balance scale that determine the efficiency and reliability. In hospitals, it guides researchers and pharmacy staff in making medicines, calibrators, and experimental solutions. electronic balance scale guarantees very low weight measurement variation which is a precondition for reproducible laboratory results. Its strength, sensitivity, and accuracy are the reasons it is indispensable in clinical laboratories, pharmaceutical testing, and biomedical research where precision is critical.

In hospital labs, electronic balance scale is utilized for the synthesis of analytical reagents that are employed in everyday diagnostics. Exact weighing guarantees the uniformity of the reagent concentration prior to inclusion into the automated testing systems. This application guarantees stable analytical performance in the areas of blood chemistry, immunoassays, and clinical research. By managing mass precision at the preparation stage, electronic balance scale allows laboratories to control reproducibility through various testing cycles, thus being an ally to reliable diagnostic results and internal quality control in hospitals.

The ongoing evolution of regulations will see the electronic balance scale adding features for compliance support that will be more advanced. Hospital lab audits and accreditation standards will be met with the help of the documentation functions and secure data storage. This future trend will greatly improve the quality management processes in all hospitals and research labs.

The maintenance of electronic balance scale involves the aspects of storage and inactivity care that come first. The balance should be protected from dust and vibration when it is not in active use. Periodically checking the operational status during long storage prevents unnoticed performance drift. These practices guarantee that electronic balance scale is still capable of accurate use in laboratories, medical and hospital settings.

Medical research laboratories rely on electronic balance scale to determine the weight of samples for their experimental procedures. No matter if weighing chemicals, biomolecules, or powders, accuracy is vital for repeatability. Scientific workers apply electronic balance scale so that slight changes in sample weight do not affect the validity of the results. The application of this tool helps to enhance the reputation of the laboratory, the quality of the experiments, and the uniformity of the research conducted in hospitals or drug companies.

Q: What is the main purpose of an Analytical Balance? A: Its purpose is mainly to measure very tiny sample masses with the utmost precision in laboratories and hospitals. Q: What is the typical weighing range of an Analytical Balance? A: The weighing range for the majority of analytical balances is from 0 up to some grams with a resolution of micrograms or milligrams. Q: What environmental controls are necessary for an Analytical Balance's operation? A: Airflow, vibration, and temperature changes should not only be avoided but also prevented in the room where the scale is situated. Q: Is an Analytical Balance permitted in a hospital laboratory? A: Yes, it has indeed found widespread usage for the preparation of reagents, calibra¬tion, and drug development applications. Q: What should be the frequency of calibration for an Analytical Balance? A: The calibration interval is subject to the degree of use and the particular laboratory requirements.

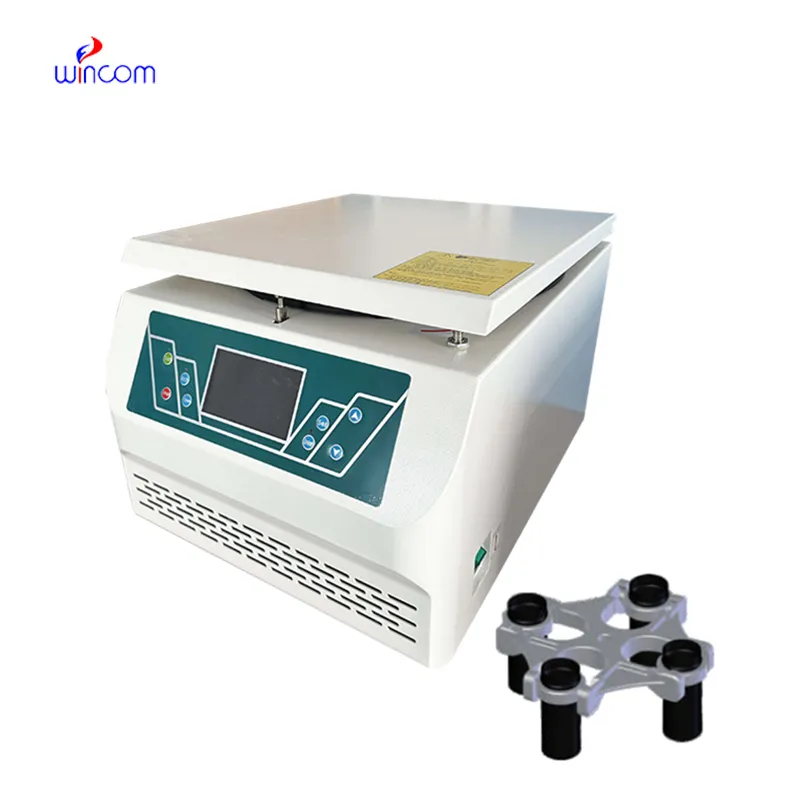

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are planning to upgrade our imaging department and would like more information on your mri machin...

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China