The x ray inspection machine has been engineered with utmost care and provides unmatchable performance in the most difficult settings. The system incorporates an automatic position system that helps with accurate orientation of the patient. The x ray inspection machine provides different parameters depending on the part of the body being imaged. This helps in getting clear images.

The x ray inspection machine is used in airport and security scanning to scan cases and detect prohibited items, demonstrating its use beyond medical purposes. In the manufacturing industry, it is used to analyze welds, materials, and electronic components to assess their integrity. The x ray inspection machine is used to achieve quality control in manufacturing and engineering.

The next generation of the x ray inspection machine would be oriented toward digital transformation through intelligent image algorithms. Machine learning would enhance the pace of image reconstruction and image clarity. The x ray inspection machine would be made wireless and portable to enable remote diagnosis and mobile healthcare facilities.

The x ray inspection machine requires careful attention to ensure imaging accuracy and equipment safety. The housekeeping staff must test system performance on a regular basis, including tube voltage, exposure timing, and detector status. The x ray inspection machine should always be turned off when being cleaned and checked routinely for mechanical or electrical wear.

The x ray inspection machine represents an important diagnostic tool that functions by using controlled X-ray radiation to create images of the bones, organs, and internal structures of the body. The equipment assists healthcare providers in diagnosing ailments such as fractures and infections with high accuracy. The x ray inspection machine equipment is usually found in hospitals and dental clinics as it provides efficient imagery services that aid in comprehensive diagnoses. The equipment's efficiency makes it an important aspect of modern medical facilities.

Q: What types of x-ray machines are available? A: There are several types, including stationary, portable, dental, and fluoroscopy units, each designed for specific diagnostic or operational needs. Q: Can digital x-ray machines store images electronically? A: Yes, digital x-ray machines capture and store images electronically, allowing easy access, sharing, and long-term record management. Q: What safety precautions are required during x-ray imaging? A: Operators use lead barriers, dosimeters, and exposure limit controls to protect both patients and staff from unnecessary radiation. Q: How often should an x-ray machine be inspected? A: It should be inspected at least once or twice a year by certified technicians to ensure compliance with performance and safety standards. Q: Can x-ray machines be used in veterinary clinics? A: Yes, many veterinary clinics use x-ray machines to diagnose fractures, organ conditions, and dental issues in animals.

The microscope delivers incredibly sharp images and precise focusing. It’s perfect for both professional lab work and educational use.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

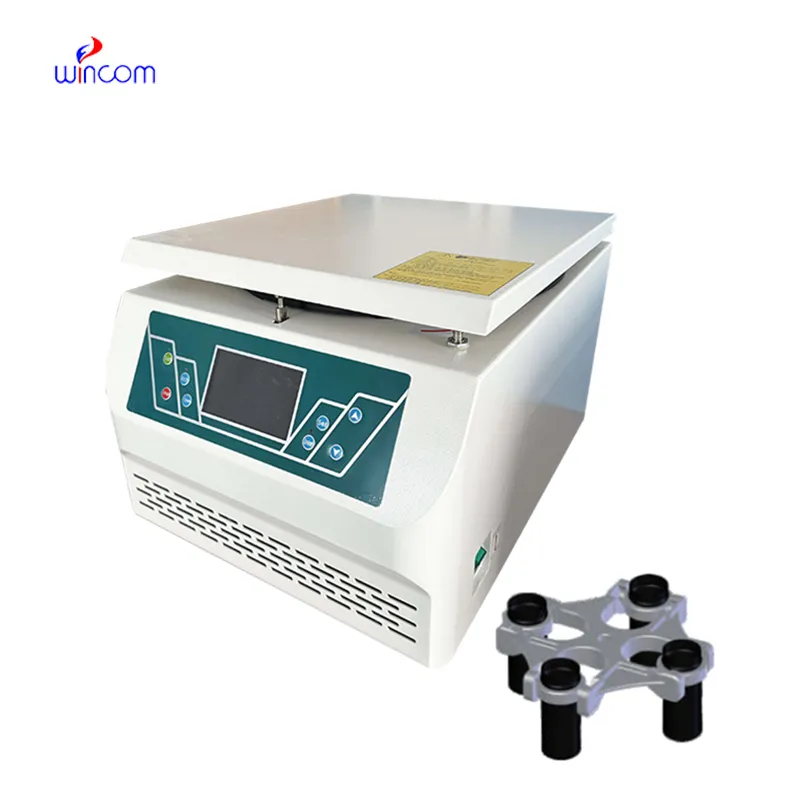

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China